blynkinsights©

A Data Analytics Digital Twin for Pharma PlantsA Data Analytics Digital

Twin for Pharma Plants

Twin for Pharma Plants

Enable your manufacturing teams to harness clarity, data and insights. Improve efficiency, control and cost of goods.

Say goodbye to lack of visibility, hidden inefficiencies and low control through the insights of data.

- The opportunityThe Pharmaceutical Manufacturing industry is under more pressure than ever to improve efficiency, process control and cost of goods. One way to achieve this is through effective utilisation of their production data.

- Slow, costly projectsOrganisations are currently reliant on slow and costly projects in their attempt to convert this data into the actionable insights. These projects are often performed far from the real needs and nuances of operations, delivering questionable value and being difficult to maintain.

- Lack of toolsManufacturing experts are those best placed to leveraging this data for the creation of true value. Unfortunately those experts don't currently have the tools available to make use of that data in a fast and intuitive way.

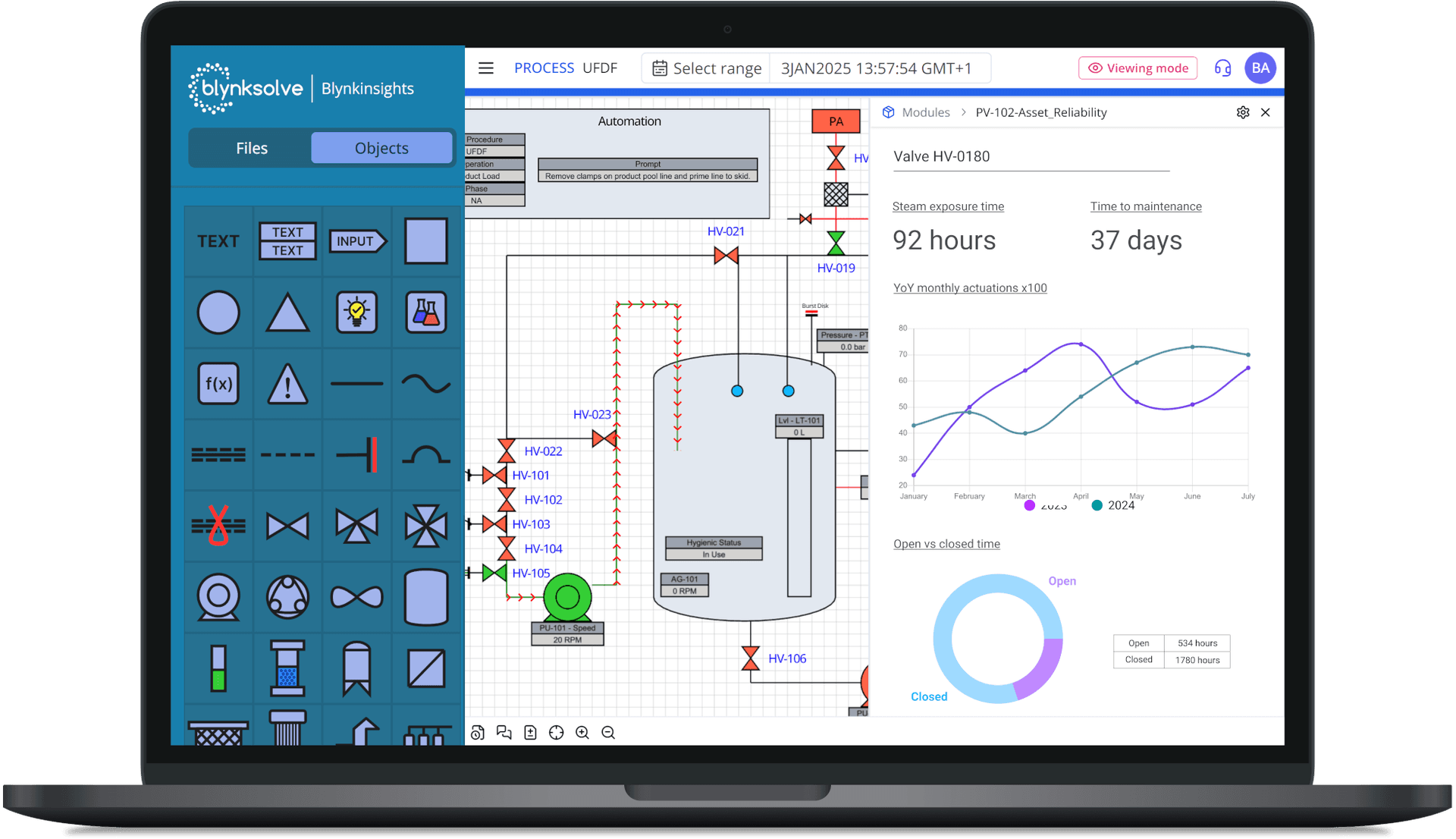

Data Visualisation,

Monitoring and Analytics

Made Easy.

Data Visualisation, Monitoring and Analytics Made Easy.

An intuitive, visual and realtime data platform for your pharma plant operations and processes. Integrate with your facilities existing data sources such as Data Historians.

Clarity

Improve visibility and democratise data that's already being generated in your plant.

Control

Enable a more proactive approach to control and risk to catch problems before they occur.

Efficiency

Achieve greater plant optimisation by identifying inefficiencies, variances and bottlenecks.

Built by pharma for pharma.

Built by pharma

for pharma.

Operational Efficiency

Automatically measure cycle times to find opportunities for improvements, e.g. common cycle repeats. Setup alerts when hygienic status are nearing expiry or when usages running low.

Process Control Monitoring

Create alert thresholds on process parameters and which automatically send emails to SMEs if triggered. Examine generated datasets to view trends over time and understand possible parameter drifts.

Asset Lifecycle Optimisation

Monitor asset usage such as valve actuations, number of SIPs, pump performance to drive data based predictive decisions and maximise longevity.

Empower your Experts.

We are on a mission to connect people, process and technology in pharma manufacture. Speak to us today to learn how Blynksolve can help you and your team achieve manufacturing excellence.